Equipment Dealer Technical School Advisory Board Support Plan

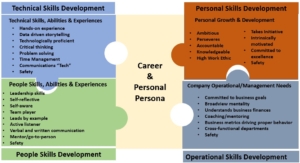

Our new guest writer, Ron Wilson has had the honor to work 41 years in the dealer equipment network in roles that included various parts and service management positions. He has spent time in the marketing department creating a data analytics team to utilize various data sources to improve existing and identify new revenue channels. Implemented pricing models that established market-based pricing models in the product support areas. He has expanded a training department’s capabilities to support technical and people skills development that included applying the Kirkpatrick training model and implementing virtual training relating to the technical and people skills development during the pandemic. Introduced dealer classes that qualified for college credit at the community college level and transferred toward a four-year degree program at the local university. His first blog post for Learning Without Scars is a valuable contribution to our Lifelong Learning series: “Equipment Dealer Technical School Advisory Board Support Plan.”

Equipment dealers, other donors, and the various technical schools spend a considerable amount of time, effort, and finances to support the ongoing efforts of education and training relating to our industry. Unfortunately, often the contributions are not properly aligned with providing the best educational environment for the students, and our future employees.

The following information is to provide a guide that will review, identify, and provide focus of the resources that are being provided to the various technical schools. This is only a guide, and does not include all the answers, but does provide directions that will improve the education and knowledge of our industry’s future employees.

Table of Contents for the Technical School Advisory Board Support Plan

- Purpose and Roles of the Technical School Advisory Board

- Structure of the Technical School Advisory Board

- Planning and Conducting Technical School Advisory Board Meetings/Events

- Assessing the Support to the Technical Schools

- Levels of Involvement with Various Technical Schools

- Industry Involvement in Technical Training

- Consolidating various programs to meet the needs of training the students.

- Agreement Regarding Donation of Equipment for Training Purposes

Purpose and Roles of Dealer’s Technical School Advisory Board.

Purpose Statement:

The purpose of this guide is to help in the development and management of the relationships with the various schools based on their Career and Technical Education (CTE) programs that are related to the skill sets needed within equipment dealerships. The focus of the support provides a common approach for industry and education to work together to close the gap in skill sets and the number of vacancies in the technician job roles within the dealership.

Advisory Board Roles:

The dealer’s Technical Training Manager is responsible for maintaining a current list of the CTE schools, points of contact, and ongoing relationship with each school based on an individual plan for each school.

Advisory Board Members:

Recommendations of who should serve on the Advisory Board:

- The equipment dealer’s Training Manager

- The equipment dealer’s Recruitment Manager

- General Service Managers including various areas such as Machinery, Rental, Engine/Truck & Trailer, and Fleet Service operations.

- General Service Managers may appoint someone to represent a specific geographical area within the dealer’s territory.

- Advisory board members are assigned to support the overall needs of dealership.

Relationship with Each School:

The relationship with each school may vary based on the:

- Capabilities (facility, faculty, and location) of the school to meet the local needs for of the dealership.

- Desire of the school to support the dealer’s technician development requirements and participation in the educating of students in the related industry.

- Location of the school

Scheduled Meetings:

- Annual Educational Summit held at the equipment dealer’s Training Department to share accomplishments, skills needed, and support needed for the schools

- Invite instructors, Program Deans, Student Advisors, and others that have the responsibility for the success of students within the school’s Career and Technical Educational programs.

- Actively participate in the individual school’s Advisory Board meetings, written communication is sent to the dealership’s Corporate & Technical Training Manager

Structure of the Dealership’s Technical School Advisory Board.

Role of the equipment dealer’s members of the Technical School Advisory Board:

To define the dealer’s specific training needs and assist in the communication and development of training material that will link the specific schools to the skill level requirements of the equipment dealer’s service operations. The intent is to close the gap on the material being taught in the technical schools’ basic skills, as compared to the needs within the dealership’s shops.

Dealer members will at least include:

- Corporate and Technical Training Manager

- General Service Mangers (Machinery, Rental, Engine, Truck & Trailer, fleet service areas)

- Recruitment/Human Resource representative

Technical School members will at least include:

- Instructors from the technical schools

- Dean of instructions from each school

- Career Advisors from each school

The technical school’s participation will be critical to assist in the types of support needed for each school. The support provided can range from serving on the school’s advisory board, providing technical material that can be adapted to the school’s curriculum to meet the needs and obtaining classroom aids the schools can utilize within their programs.

Planning, Conducting, and Participating in Technical Schools Advisory Group Meetings/Events.

Planning, conducting, and participating in the technical schools’ advisory meetings/events will fall into three categories:

- The dealer’s Technical Schools Advisory Meetings/Events: An event organized by the dealership to support/participate/build a one-on-one relationship with a specific school. The dealership will identify specific needs that require a close relationship with a specific school, or group of schools.

- Technical School Advisory Meeting/Events: Most of the technical schools are required to conduct industry advisory meetings. These meetings include a variety of topics ranging from budgets/finances, classroom material, review of student needs, and participation opportunities for the dealership to support the school that may result in connecting with potential future employees.

- Industry wide involvement may include working with various schools, dealership customers, OEMs, and competitors. The combined efforts may include events where the dealership will work with customers and possibly competitors to discuss, develop, and conduct events that supports the overall needs of developing and promoting the careers of technicians within the industry.

Assessing the Support to the Technical Schools

Limited Resources- We all have limited resources (time, talents, and dollars), therefore it is critical to focus on areas of positive impact with high results. In an effort to match the needs of the school and the support the dealership can provide a list of criteria, as a guide in defining the type and level of support to be provided to the technical schools.

The criteria will focus on:

- Linkage to dealer’s technicians’ needs by location- for example supporting the store in area of the territory may be a little different than supporting a school in a different part of the dealer’s territory.

- Skill level requirements- The type of skills may place focus in support of some schools. For example, an immediate need for welders will be a higher priority for schools that have a welding program.

- Short term/long term requirements- School relationships should be long term focused. It takes time to:

- Build relationships- understanding our industry needs and the school requirements.

- Develop curriculum the schools can apply within the classrooms that relate to our industry.

- Obtain resources that meet the needs of the curriculum and to conduct the classes.

- Current capabilities of the school- It is important to review the individual school capabilities and determine how the dealership can assist the schools. The most common support that can be provided to a school are:

- Content material-Providing content for the classes provides an opportunity to teach the material that is important to the dealership. Some OEM’s allow the use of training material for schools. Instead of providing all of the material at once. A distribution plan per school should be utilized to assist with the introduction, teaching, and application of the material.

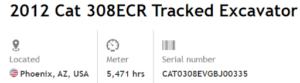

- Training aids- can range from small parts to large components that can be utilized in lab exercises in support of hands-on experiences.

- Instructor support- The dealer’s instructors may lead classes to the school instructors in specific topics (General Engine, Hydraulics for example) to prepare the school instructors to apply the material being provided within the school’s classes.

- Estimated financial support- There may be some opportunities for financial support to assist schools in accomplishing initiatives that will align with dealers’ longer term needs. The recommendation is to avoid the one-off donations for shop supplies (oil, filters, antifreeze) due to these being budgeted school expense items. The focus should be on longer-term needs.

An assessment form should be developed to assist in the review of each school. The assessment is only a guide to decisions being made to determine the level of support to a school.

Levels of Involvement With Various Technical Schools

Involvement with the various technical schools may occur through various avenues:

- Dealer/OEM Technician Degree Program- Participate in promoting the program to various individuals that have an impact in raising the awareness and interest in careers as technicians, and within our industry. This will include working with various levels within the school programs, administrators, local community activities, and other associations that can have a positive impact in attracting talent to the dealer’s/OEM programs for technician development.

- Advisory Board support to the individual schools- Assign Dealer employees to serve on the individual school’s advisory boards. The assigned employee will most likely be a dealership instructor that can recognize training needs, and opportunities to assist the specific school. The employee will have levels of “authority” to assist the school based on the needs assessed. It is important the instructor/dealership employee be seen as active/engaged and can assist in making decisions on behalf of the dealership in support of the school. Each meeting will be recorded in some type of form that identifies the date of the meeting, what was covered and includes a description of a need (if determined).

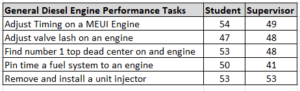

- Dealer/OEM Training Material- The various dealers/OEMs have training curricula covering various systems ranging from basics to more, advanced service repairs, and diagnostics. The course design instructs three primary areas: Foundational Knowledge, Skills Practice and Skills Assessment. Each module should contain a Facilitator Guide, Student Guide, Activity Workbook, PowerPoint Presentations, including knowledge and practical assessments.

- Technical classes conducted by a dealer training instructor- Providing an opportunity for technical school instructors to continue learning about the OEMs’ product line, components and systems will increase the quality of students coming out of the program. The class offering can best be provided to a group of schools’ technical instructors going through the class together. These classes provide networking between the instructors and the dealer’s instructors as well. As part of the class, the Dealer/OEM material will be provided that will allow the instructor to take the material back to their local campus and apply within their program.

Equipment Dealer’s Industry Involvement in Technical Training

There are several opportunities for dealerships to participate in the development of industry wide skilled technicians by working with the various technical schools. The following are some examples of being involved at an industry level, which may still be combined with a technical school at some level.

Local Trade Associations

- Associated General Contractors of America is an example of a local trade association that continually seeks opportunities to train technicians within the contractor association’s membership.

- Dealers/OEM’s develop technician training classes that will meet the various State Technician Apprentice programs. This can be a fee-based program that provides classroom, lab exercises in a shop environment, and machines to support the successful completion of the program.

National Trade Associations-

- Associated Equipment Distributors (AED) is an international trade association representing companies involved in the distribution, rental and support of equipment used in construction, mining, forestry, power generation, agriculture and industrial applications. There are various programs available through AED that can support local high schools, community colleges, and technical schools in a common educational foundational approach related to teaching and training future technicians. The programs can include:

- Classroom material

- Support through the AED Foundation

- Technician assessments

- Assessment tools to evaluate educational facilities.

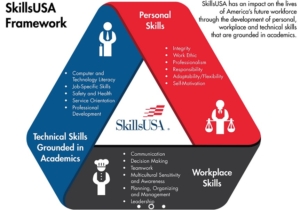

SkillsUSA–

Is a partnership. students, teacher. and industries working together to ensure America has a skilled workforce. SkillsUSA empowers its members to become world-class workers, leaders and responsible American citizens. SkillsUSA improves the quality of America’s skilled work force through a structured program of citizenship, leadership, employability, technical and professional skills training. The program enhances the lives and careers of students, instructors and industry representatives as they strive to be champions at work.

SkillsUSA serves more than 300,000 students and instructors annually. The organization has 13,000 school chapters in 54 state and territorial associations. More than 14,500 instructors and administrators are professional members of SkillsUSA.

For information about the national level, visit skillsusa.org

Did you enjoy this blog? Read more great blog posts here.

For our course lists, please click here.