Facts Vs. Feelings: Recruiting Technicians

Facts Vs. Feelings: Recruiting Technicians

Guest writer Isaac Rollor highlights the importance of building relationships with your communications at your business in “Facts Vs. Feelings: Recruiting Technicians.”

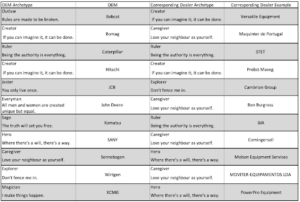

I do not know the exact source of the statement “Facts don’t care about your feelings” but it’s a statement I have heard many times recently. This statement as I heard it was not applied directly to the heavy equipment industry, but I do feel it warrants some reflection. The heavy equipment industry is really invested in facts. Hard evidence. Data. Not a bad thing. In fact, it is a source of certainty that is lacking in many other industries. Technicians are one of the most factual focused working groups in our industry and rightfully so. To be successful, technicians must focus on facts pertaining to safety, quality of work, billing etc. Facts are important. The problem with facts is that facts alone do not cause someone to act. In my experience emotions cause action.

My hypothesis. One reason technicians are not entering the heavy equipment workforce at a fast enough rate is because OEM’s and dealers are focused on facts during recruiting and rarely focused on emotion. Industry hardened professionals love facts because these facts have led them to remarkable success. Here is a splendid example, if a technician masters the repair manual’s process of replacing, diagnosing, and repairing a certain OEM’s machines they will be considered successful, receive promotions, and make more money. All they had to do was follow the facts, such as processes, procedures, torque specs etc. and they achieved success. When I speak with technicians who have 20-30 years logged repairing heavy equipment, I like to ask them why they started and stayed in the industry. The answer is usually rooted in emotion. This may be related to their family, or even their own internal desire but it is typically a love of something that moved them to become a technician and eventually become an expert technician, service manager etc. The feeling or emotion motivates someone to come to terms with the facts.

When I hear recruiters speak to potential technicians and lead off with statics or data and facts about the industry/job I always cringe a little bit. Starting a career or even changing jobs within the industry is a crucial decision for most people. If you dig deep enough, you are highly likely to discover that this decision is rooted in emotion. An OEM or dealer competing for a scarce resource such as technicians should carefully examine the strategy being used to attract and retain top talent. Let’s make a quick comparison of facts-based messaging and feelings-based messaging. How would you respond if you were a capable technician just out of trade school and you were making a career decision based on the following job discussion with a recruiter?

Facts based job discussion:

Heavy vehicle and mobile equipment service technicians at ABC company typically do the following:

- Consult equipment operating manuals, blueprints, and drawings.

- Perform scheduled maintenance, such as cleaning and lubricating parts.

- Diagnose and identify malfunctions, using computerized tools and equipment.

- Inspect, repair, and replace defective or worn parts, such as bearings, pistons, and gears.

- Overhaul and test major components, such as engines, hydraulic systems, and electrical systems

- Disassemble and reassemble heavy equipment and components.

- Travel to worksites to repair large equipment, such as cranes.

- Maintain logs of equipment condition and work performed.

Heavy vehicles and mobile equipment are critical to many industrial activities, including construction and railroad transportation. Several types of equipment, such as tractors, cranes, and bulldozers, are used to haul materials, till land, lift beams, and dig earth to pave the way for development and construction.

Heavy vehicle and mobile equipment service technicians repair and maintain engines, hydraulic systems, transmissions, and electrical systems of agricultural, industrial, construction, and rail equipment. They ensure the performance and safety of fuel lines, brakes, and other systems.

These service technicians use diagnostic computers and equipment to identify problems and make adjustments or repairs. For example, they may use an oscilloscope to observe the signals produced by electronic components. Service technicians also use many different power and machine tools, including pneumatic wrenches, lathes, and welding equipment. A pneumatic tool, such as an impact wrench, is a tool powered by compressed air.

Service technicians also use many different hand tools, such as screwdrivers, pliers, and wrenches, to work on small parts and in hard-to-reach areas. They generally purchase these tools over the course of their careers, often investing thousands of dollars in their inventory.

After identifying malfunctioning equipment, service technicians repair, replace, and recalibrate components such as hydraulic pumps and spark plugs. Doing this may involve disassembling and reassembling major equipment or adjusting through an onboard computer program.

Feelings based job discussion:

Many heavy equipment technicians at ABC company report feeling a sense of freedom because they are responsible for their own service truck, tools, and schedule. How would it feel to have control over your own schedule and work experience? Is this something that is important to you?

Notice the difference? Facts based discussion leaves little room for tactical questioning of the candidate. To the contrary a feeling-based discussion can easily omit many of the hard facts and cut directly to the emotional reasoning for being interested in a technician position. The great part about leading with feelings is that facts can still be presented but these facts can now be hand-picked to support the feeling the technician wants to have.

Here is my challenge to you, lead with feelings instead of leading with facts. See how many times you can get your potential technicians to “feel” a certain way about the job. Once the feelings are identified use your facts to support their feelings and allow them to arrive at a career decision that they “feel” most comfortable with. I think the results may surprise you.