1% Increase in Income Equals 2.6% Reduction in Expenses

Guest writer Ron Wilson dives into the financial management scene with this week’s blog: 1% Increase in Income Equals 2.6% Reduction in Expenses. He even touches upon something Ron Slee mentions frequently: the downside of discounts.

During complicated economic times businesses tighten up on expenses, spending, and accounts receivable.

Rafi Mohammed, in his book “The 1% Windfall” provides an additional effort that can assist in meeting the needed changes to the bottom line.

Basically, the concept revolves around increasing income by 1%, without increasing the cost of sales, or reducing direct expenses.

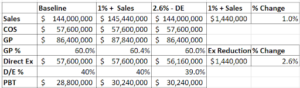

The example below shows that a 1% increase in sales (without impacting cost of sales or direct expense) equals a 2.6% reduction of direct expenses. Apply your organization/department gross profit and pretax percentage to see the impact it has on your own organization.

We have all been through the difficult experience of reducing direct expenses, and it can be very painful.

Here are a few examples that can help to make a positive impact on sales without adjusting the direct expenses areas.

Current Status of Discount Programs– often discount programs are provided to customers based on a request from a salesperson. No doubt the programs may have been needed at a specific point in time, but a review of discount programs may show discounts being given that are not providing the expected increase in sales. Often the OEM provides some type of shared discount program over a specific timeframe. It is important to verify customers’ discounts reflect the OEM’s current program. An OEM may discontinue a rebate program and the dealer may not have applied the same changes and unintentionally may be caring the full burden of the discount being provided to the customer.

Effectiveness of Discount Programs-Verify the discounts are providing the expected results, which is usually increased volume, or expanded use of other products and services within the dealership. If the discount program was not effective, a different approach may need to be reviewed with the sales representative.

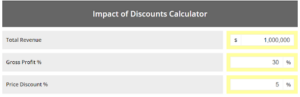

Below is a handy website that shows the impact discounting has on gross profits.

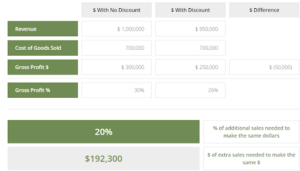

The example below applies to a 10% discount on $1 million in sales. Sales need to increase 20% to make up the same dollars.

https://www.growthforce.com/blog/how-giving-discounts-can-destroy-your-business-profits

This can be a great tool to share with the sales representatives when discussing providing a customer with a discount. What can be expected in increase volume over time?

Providing Repair Options can offset the discount a customer is wanting on a component rebuild, for example. Rebuild options providing a “good-better-best” offering can accomplishing the customers rebuild needs within a specific price range. The variable rebuild options allows the dealer to rebuild a component that meets the level of rebuild needed by the customer within a selected price range. The repair options eliminate the “discount” of a full rebuild while providing a price based on the level of rebuild needed by the customer.

Value Based Pricing requires understanding the customers’ needs and priorities. For example, a customer is focused on reducing the hazards/injuries related to changing ground engaging tools (GET) on a piece of mining equipment. Promoting reduction of the number of GET changes will contribute to reducing the hazards as well as downtime to complete the GET change out. It may not always be about the dollars and cents.

When developing value statements your existing customers can be a great resource to find out what value you bring. Ask your customer to explain the real value of your offer. This will provide a view of their perspective, while building relationships with customers and at the same time it gives you a chance to learn an incredible amount of invaluable information.

Below is an example of a value statement that has identified four areas of importance to the customer. This information was taken from an ESCO GET (Ground Engaging Tool) promotional piece. As can be seen there is no discussion about “discounts,” the discussion is related to “value add” offerings:

Increased Machine Availability

- Superior alloys and optimized system profile result in longer-lasting components

- Simple, intuitive locks provide safer, faster parts replacement.

- Reliability and wear life unmatched in the industry keeps machines operating with minimal downtime.

Lower Maintenance Costs

- Proprietary alloy, increased lip protection and large bearing areas extend operating intervals.

- Longer lasting and more dependable G.E.T. reduces planned and unplanned service events.

- Quick and easy parts replacements by fewer crew members, with no hot work required.

- Shrouds and adapters are engineered to protect more of the Nemisys lip leading edge, extending the service life between lip rebuilds by up to 70%

- Improved wear metal placement increases shroud life by up to 30%

Lower Total Parts Expense

- Longer lasting and more dependable G.E.T. results in fewer parts purchased versus competitors.

- Fewer parts purchased reduces mine site inventory to ship, stock and manage.

Improved Safety

- Keep your crew away from crusher maintenance through superior locking systems that keep teeth and shrouds on the lip.

- Safer installation and removal with integrated pry points and compatibility with the ESCO SecureLift™ system

Best of Both Worlds

1% increase in Sales Without increasing Cost of Sales to Improve the Bottomline: It would be unrealist to think the 1% increase model is the only option. No doubt there needs to be a combination of both direct expense management and reviewing the pricing models and programs currently in place. Below are some pros and cons that will show the importance of combining the two:

Advantages of the 1% Increase in Sales to Improve the Bottom Line:

- Incremental growth may seem small but overall can have an enormous impact on the bottom line.

- Growth in the business comes from income growth, not from reducing expenses.

Disadvantages of the 1% increase in Sales to improve the Bottom Line:

- The 1% increase is not guaranteed and takes time to implement. Reviewing and developing impactful value statements takes time and resources to research, understand, and develop.

- Takes time to implement, communicate, and evaluate the results of the changes implemented.

Reducing Direct Expenses to Improve the Bottomline:

- Has an immediate impact depending on how drastic the effort?

- May improve efficiencies through improvement/streamlining processes.

- Requires a focus on the core business and focus on what is important.

The best Solution is a Blending of the Two:

Take some time to review the various recommendations provided in “The1% Windfall”, while reviewing the rest of your key performance indicators, to provide a balanced improvement to the overall financial results.

Did you enjoy this blog? Read more great blog posts here.

For our course lists, please click here.

AVID – An Academic Powerhouse

AVID – An Academic Powerhouse

Curriculum Designer Caroline Slee-Poulos is back with a guest blog on the topic of AVID – An Academic Powerhouse.

When you get right down to the nitty-gritty of things, Socrates was right. No, I don’t mean our Owl, Socrates, the Learning Without Scars logo. I do mean the ancient Greek philosopher who was generally regarded as a figure to ridicule during his own time. His methods of questioning and building argument are referred to as the “Socratic Method” to this day.

If you think about it, teachers are treated the same way: they are heroes to villains, archetypes more than individuals. This blog post isn’t about that, however. It’s about a program that has been quietly at work for 43 years: AVID.

AVID stands for Advancement Via Individual Determination. It is taught as an elective in public schools, and was developed by Mary Catherine Swanson in 1980.

The program was a response to a bussing program taking place in San Diego, California. With the arrival of students who were economically and otherwise disadvantaged, there was a belief that these students could NEVER be college ready. Today, AVID is a program that focuses upon both career and college readiness. The greatest value, in my opinion, is the emphasis it places on questions. An AVID student is required to do a tutorial (usually twice each week) in which the student must bring in a question about one of their content-area classes. This process asks students to go through their process of learning, understanding, and problem-solving to pinpoint where they are stuck. In response to this question, students (including peer tutors) work together to help the student answer their question. They do this by…asking MORE questions!

The results of this method are wonderful: students are able to refine and solve their own questions, as well as building collaborative skills, communication skills, and critical thinking skills.

As we look at the struggles faced in the job market today, we often here that new hires are lacking the critical thinking skills required to succeed on the job. In one of our classes, we highlight open-ended questions as a key tool for engaging with customers.

AVID classes address both of these issues, starting in elementary school. Some schools are working to bring these methods into every content-area class, as opposed to just an elective. Although AVID was created as a response to an opportunity gap, its benefits are applicable to all students, and in more places than just the K-12 public school classroom.

As a teacher and curriculum designer, I look at AVID as being on a spectrum with other courses and educational opportunities, including our own here. It is never too late for a student to gain a new skill. We always continue to learn, as long as we live.

Today, I encourage and challenge you to bring questioning into your academic vocabulary. It will change the way you think about problems.

Did you enjoy this blog? Read more great blog posts here.

For our course lists, please click here.

Unraveling Mysteries: The CSI of Industrial Component Failure Analysis

Unraveling Mysteries: The CSI of Industrial Component Failure Analysis

Guest writer Jim Dettore gets into the nitty-gritty of CSI with “Unraveling Mysteries: The CSI of Industrial Component Failure Analysis.”

Introduction:

In the world of engineering and manufacturing, industrial component failure can be a perplexing puzzle to solve. Just like a crime scene investigation (CSI) unfolds on TV, engineers embark on a journey to uncover the truth behind why a vital industrial component failed. In this blog post, we delve into the intriguing similarities between industrial component failure analysis and investigating a crime scene. From gathering evidence to reconstructing events, let’s uncover the secrets of these parallel worlds.

Just as a crime scene holds crucial evidence, the site of an industrial component failure is a treasure trove of information. Engineers meticulously examine the surroundings to find clues and collect physical evidence (Facts) that could reveal the root cause of the failure.

In both scenarios, evidence plays a pivotal role. Engineers use a variety of tools, such as microscopy, spectroscopy, and non-destructive testing, to examine failed components, just as forensic experts analyze crime scene evidence to build their case.

Reconstructing events is vital in both investigations. Just like a detective pieces together the sequence of events leading to a crime, engineers trace the history of the component to understand its operating conditions, maintenance history, and any incidents that may have contributed to the failure.

Witnesses provide valuable insights in a crime investigation. Similarly, operators and maintenance personnel offer their experiences and observations about the industrial component’s behavior, which can be crucial in understanding the failure’s origins.

In the CSI of industrial component failure analysis, defects and material issues are the primary suspects. Analysts evaluate potential culprits like fatigue, corrosion, stress, or material anomalies to identify the most likely cause of the failure.

Just as crime scene investigators have advanced tools at their disposal, engineers utilize cutting-edge technology to aid their analysis. Finite element analysis, thermography, and other sophisticated techniques assist in deciphering the mystery behind the failure.

Solving a crime often involves a sudden revelation. Analysts experience their Eureka moments when the evidence finally leads them to the definitive conclusion, uncovering the “smoking gun” behind the industrial component failure.

Ultimately, both investigations seek to prevent future incidents. By understanding the root cause of a failure, engineers can devise strategies to improve design, materials, and maintenance practices to ensure similar failures are thwarted.

Conclusion:

The parallels between industrial component failure analysis and investigating a crime scene are undeniable. Both require meticulous attention to detail, a methodical approach, and the determination to solve complex mysteries. The next time you encounter an industrial component failure, think of it as an opportunity to be a detective – unveiling the truth behind the enigmatic world of engineering mishaps.

So dear readers, embrace your inner investigator and embark on a journey of discovery, for the world of industrial component failure analysis truly is the captivating CSI of engineering!

Did you enjoy this blog? Read more great blog posts here.

For our course lists, please click here.

The Top Three Heavy Equipment Jobs That No One Knows About

The Top Three Heavy Equipment Jobs That No One Knows About

Guest writer Isaac Rollor is back this week with a blog post on the top three heavy equipment jobs that no one knows about – other than technicians!

Most of my blogging in the heavy equipment world focuses on issues related to heavy equipment technicians. However, recently I was speaking with an industry insider who complained that any college aged worker looking for jobs in the heavy equipment world is bombarded by marketing towards technicians and operators. There is truly little focus on filling other technically focused heavy equipment positions that are currently in high demand. This really piqued my curiosity because it’s a true statement. Open any search engine and type “Heavy Equipment Jobs” what will you find? Jobs for operators and technicians, training for operators and technicians. Millions of dollars in search engine optimization focused to make sure that anybody who wants to be around yellow iron becomes an operator or a technician.

To be honest, this is something that was never obvious to me, though it should have been. As a subject matter expert, I always knew that there was opportunity beyond working as a technician. I didn’t promote these opportunities because I was busy making sure every knew how great being a technician is. To investigate the matter, I called up a college aged family friend who is currently considering a career at the OEM dealer level. I was quite sure that even though I had never evangelized opportunities beyond being a technician, people must know that other opportunities exist beyond the role of technician. Surely, they did, right?! My assumptions fell flat when my contact couldn’t name any other position beyond “master technician.” When I pressed him for more detail he said, “I guess a technician could work for the parts department or maybe move into sales.” No mention of the service department, no mention of failure analysis, no mention of remarketing……. because he didn’t know. No one ever told him that there were many other jobs that a highly technical heavy equipment expert could move into during a career in the industry.

As I thought more deeply about this, I realized that for many years I was like a doctor who was prescribing a particular medication because there was currently a surplus of that medication. Okay, so that’s a little over top but it makes my point. Just because there is a massive need for technicians doesn’t mean that everyone who shows interest in heavy equipment is a good fit to be technician, even if they have the aptitude or ability.

Right now, there are a lot of talented people who think that technicians and heavy equipment operators are the only positions in high demand with the heavy equipment industry. I still think that being a technician or operator is a distinguished career choice, but I would also like to offer up my top three job title picks for 2023 not including technician or operator.

Product Support Manager:

As a Product Support Manager, you will collaborate with multiple teams to deliver the best possible experience to the end user of your OEM’s product. This position can be found at the manufacturer or dealer level. Many Product Support Mangers were technicians prior to taking on this position. Having a technical background is greatly beneficial because in this role you will be guiding warranty repairs, serving as the subject matter expert for failure analysis questions and directing teams from service, parts, sales, and warranty to get a customer’s machine running again. One of the great parts about the role is that you get to travel and see a lot of interesting construction, forestry, and mine sites. All this travel requires a 4×4 vehicle and it is customary for most employers to provide you with a company vehicle.

Here are the typical qualifications/requirements for this role:

Parts Sales and Service Representative

As a Parts Sales and Service Representative you will be responsible for forecasting the parts and service that a fleet of machines will need over its lifetime and then building a strong relationship with your customers so that they buy parts from you and set up service contracts with your dealer or manufacturer. Having a technical background is always helpful when working in this position. This experience will help you connect with your customers. The parts sales and service representative (PSSTR) can work at the manufacturing level or dealer level. The PSSR will frequently bridge the gap between the service department and sales department. A lot of times the PSSR spends more time with the customer than the salesperson who sold them the fleet of machines in the beginning.

Here are the typical qualifications/requirements for this role:

Technical Trainer

As a technical trainer you will be responsible for training technicians and service personnel to troubleshoot, diagnose and repair equipment. This position isn’t a good fit for anyone with stage fright. It’s common to have 10-15 highly technical learners in your classroom ready to learn about a new product/technology. This is a highly visible role, and this position is available at the dealer and manufacturer level. As a technical trainer you will typically work for the training department, but you will frequently work with the service department, publication department and warranty department to develop content and deliver content.

Here are the typical qualifications/requirements for this role:

All these jobs are currently in high demand. It’s hard-to-find people with the skillset necessary to perform these roles at a level of excellence, but anyone who has a passion for heavy equipment can excel in these positions. If you would like to learn more about these positions, I encourage you to visit OEM websites and search for these titles. The big three heavy equipment manufactures will have immediate openings for these positions. If you want to discuss these roles in more detail, please email me directly at is**********@***il.com and I am happy to point you in the right direction.

Did you enjoy this blog? Read more great blog posts here.

For our course lists, please click here.

Wait…Wait! Don’t Sign It!

Wait…Wait! Don’t Sign It!

Guest writer John Anderson is back, with a word of caution this week, in “Wait…Wait! Don’t Sign It!”

Well at the very least let’s think about it first. Given all the changes in Dealer Systems over the past few years, you will no doubt be looking to either renew your existing services with a supplier or perhaps move to a new supplier in the upcoming year. The world has changed, and the balance of power has shifted to you, the customer, but nobody realizes it. The contracting process is your chance to exercise your newfound wisdom.

Whether it’s a hosted SaaS model as described by Greg Greedy in last week’s blog or server onsite from 2015, why do you need a contract beyond one year with a Dealer System provider? We know the barriers to change are great enough that you are unlikely to jump from system to system without some significant benefit. We know the rate of innovation is slow enough that a one-year contract won’t leave you in dust. Pricing remains competitive and there is no resource constraint that will drive prices up, like fuel or food. So why the need to sign a contract longer than one year? The purpose of the contract should be to lay out the terms of service, the “who does what” and how much. It should be used to cement expectations, establish remediation options, and even deal with ownership of data issues. None of these requires extended contracts.

With Dealer Management Systems you absorb the cost of installation and training up front. The underlying development has been done and recouped many times over. The infrastructure for hosted solutions is already in place and data centers are plentiful. You will be paying for the hardware and networking separate from the software contract. Most suppliers will chase you and apply extreme pressure to sign a multiyear contract but why? Why the need to lock you in. As I have said before the Equipment Distribution marketplace is at least 5 years behind the outside world.

Just 5 years ago if you bought a cell phone you did it under contract. That contract started at 3 years and was very penalty laden if you wanted out. As consumers felt they were being held hostage the government and upstarts entered the picture and now options range from monthly prepaid, to simple no contract month to month. The original premise was the providers needed the guaranteed revenue to be able to invest in the infrastructure but that is no longer the case.

Home and business internet was like telephone services and required a long-term commitment for the same reason. Companies like SpaceX have changed the game. Through offers like Starlink they only ask for a 30-day commitment. Gone are the 2- or 4-year covenants that made it impossible to change.

Dealer systems are no different. There is absolutely no reason a multi-year contract should be required. The recent influx of equity partners makes it truly clear from a supplier perspective. If all the existing customer base sign a 3-year contract and they already know what their profit margins are, it’s a slam dunk to sell the company or show stable growth to potential investors. A few PowerPoint slides with a projected growth target and you have an investor’s dream. What they want to do is mitigate the risk and accentuate the revenue opportunity by showing they have the market “locked up” for three years. No need to worry about performance or innovation. No risk of a new upstart with the next best thing for at least 3 years. The revenue is fixed, the risk is eliminated and a couple quick wins to show some more opportunity is all it will take to drive the value up of the software supplier for either share price or acquisition.

It is time to push back. If they need a three contract it better have a good escape clause. It should be performance driven. It should provide more than just price protection; it should offer innovation guarantees and development commitments. A good contract serves both parties. If a supplier really backs themselves and believes they are going to provide you with excellent value for the money spent, they will not require a 3-year locked in contract. Read the contract carefully and see what it provides for your business. Don’t just ask a lawyer to read it, absorb the spirit of the contract and see what it offers your business.

I say it every day, the world is changing. Business is changing. Your customer’s expectations are changing. It is time you contributed to the change. Take the time to read your contracts. Ask yourself what it provides for you. Ask why some suppliers have open 1-year contracts and others require heavily weighted 3-year contracts. Ask why it may have multiple renewal dates rather than a simple inclusion of services. Ask what both parties’ obligations to ongoing development are. Ask how you get out.

I have yet to jump from an airplane, but I check the location of the emergency exits every time I fly. Check your exits and the services before you find yourself at 30,000 feet for 3 years.

Did you enjoy this blog? Read more great blog posts here.

For our course lists, please click here.

A Tabletop Exercise: A Survey Within a Survey

A Tabletop Exercise: A Survey Within a Survey

Guest writer David Jensen continues to make observations from rural New Mexico with “A Tabletop Exercise: A Survey Within a Survey.”

As a first responder in the Fire Service, a firefighter learns the value of a tabletop exercise. An actual tabletop containing several buckets of sand provides the platform for creating a simulation of a wildfire incident. We survey any number of data points (weather, topography, fire behavior) to build a simulation. The simulation only comes to life when you match the data points with a small relevant set of behavioral questions. The questions form the tabletop exercise. The choices presented on the tabletop are neither right nor wrong. The questions do require a behavioral answer. In effect we are conducting a survey within a survey. When you conduct the tabletop exercise, the data points (survey 1) translate into actual behavior (survey 2) on the ground during the fire simulation. The exercise allows you to drill down to the decision-making tree of the Incident Commander. The survey within the survey.

As an HR Professional, I again experienced the importance of a tabletop exercise built on behavioral questions. As an example, a key HR deliverable was a location-wide employee satisfaction survey. The initial data collection was outsourced to an independent collection service. The extensive surveys covered many aspects of employee satisfaction ranging from pay and benefits to the choices in the vending machines in the breakroom. Upon completion of the survey, the collection service would provide a vast amount of data. The data dump was not the end of the process, it was the start. After reviewing the data, a tabletop exercise would be assembled to be used during the follow up with small group employee meetings.

The tabletop questions would provide an assessment of the motivation and the concerns of the small group. The survey within the survey. The tabletop was the link between data and behavior. The issue regarding choices in the vending machine may really be about a manager’s unacceptable behavior.

The tabletop exercise with a few relevant behavioral questions can be applied to a variety of data collection efforts. Our legal system is a discovery phase leading to a court room tabletop exercise. The foundation of effective job interviewing is asking performance and behavioral questions drawn from a resume. The survey within the survey. The value of a 360 supervisory assessment comes to life when you follow up with an effective tabletop exercise with the supervisor receiving behavioral coaching. Paper and pencil inventories concerning personality, values or ethics become useful when followed up with and validated by a tabletop exercise. Again, a survey within a survey.

In some circumstances, a short concise tabletop exercise may stand in place of extensive and expensive data collection. The right set of relevant questions can identify trends that will point you in a direction. Recently, I developed a tabletop exercise that asks a small number of behavioral questions. The possible answers trended towards an experience-based solution or an option-based solution. The provided choices were neither right nor wrong. How participants responded was then matched to data on individual participant success in one-to-one customer communication and customer retention. A survey within a survey.

Bottom-line; in this era of super computers and AI, a few relevant questions presented using a tabletop exercise in a person-to-person encounter should not be overlooked, it should be embraced. It is the person-to-person conversation found in the tabletop exercise that translates data into behavior.

Did you enjoy this blog? Read more great blog posts here.

For our course lists, please click here.

Combat the Mid-Year Slump

Combat the Mid-Year Slump

Guest writer Jennifer Albright is back this week, with practical words on how we can all combat the mid-year slump.

And suddenly…we’ve entered the second half of the year. In January many of us are full of New Year, New Me attitude and full of energy in anticipation of everything they’re going to accomplish in the coming year. But somehow by the time we reach July it’s more of a “how did we get here so quickly?” type feeling. A “where has the time gone, year-end is going to be here before you know it” vibe. A lot of my colleagues have expressed feeling burned out and overwhelmed.

So, what can we do to get back to where we were – full of hope and looking forward to the year ahead? Here are a few things I do to change my outlook when the summer slump hits.

Take a vacation! Seriously. Even if you can’t leave town, taking some time off can-do wonders for the mind and body. Get some rest. Catch up on whatever random chores you’ve been meaning to do. Binge Ted Lasso and sit on the sofa with the good snacks. Work in the garden, play with the kids, plan some date nights with your other half, spend time with friends. Whatever serves to help you reset and relax. Don’t pretend you don’t have time.

Pull out the strategic plan you so excitedly put together back in December/January. How have things been going? Is there a task that you’ve been putting off that can be revisited? Do January’s goals still align with today’s priorities? For me, it can be easy to get bogged down in the everyday grind so special projects can fall by the wayside if I’m not making a conscious effort to get them done. But on the flip side I’m also a list person so being able to check things off brings a ridiculous amount of joy. I tend to take the snowball approach – finish the smallest tasks first, then use that momentum and feeling of accomplishment to attack more significant projects.

If you find that you haven’t had the time to deal with anything on your 2023 plan, that’s okay – there’s still time. Put a weekly or monthly reminder in your calendar or schedule a recurring meeting to give yourself time to focus on these tasks. If you’re easily distracted, the structure of a scheduled meeting can help to ensure that you put in the time and energy to get these things done.

For tasks that you have completed, have you been measuring progress? Too often we check items off a list, never to be thought of again. If you’ve implemented a new system, are you using the data to create value? If you’ve negotiated new supplier contracts, have you measured cost savings or efficiency to ensure that what you’ve put in place is having the intended effect? Survey your folks to see if the initiatives you’ve put in place are solving the challenges, you’d set out to solve. Fine tune where you can – this not only builds trust within your team and shows that you’re listening and care about their input, but it ensures that you’re getting the most value for your efforts for the long haul.

Finally, sing your praises! Too often no one knows what we’ve accomplished unless we tell them. Why wait until your next performance evaluation? Sharing your wins gives you positive free press and opens a dialog with your colleagues where you can find new initiatives that need attention or ways to make what you’ve accomplished even better. It can also prevent duplication of efforts; if others don’t know what you’ve done, they may be trying to address the same challenges and inadvertently waste time that could be better spent elsewhere. In turn, this is a great way to generate some much-needed motivation and re-gain momentum to finish out the year strong.

To sum up, this can be a challenging time of year, but it doesn’t have to be. Take a break if you need one. Revisit what you said you were going to accomplish and see how you’re measuring up. Measure results and talk to your colleagues to make sure that what you’ve done is hitting the mark or adjusting as needed. And finally, be sure to share what you’re doing.

Did you enjoy this blog? Read more great blog posts here.

For our course lists, please click here.

The Role of SaaS Platforms in the DMS World for Heavy Equipment Dealers

The Role of SaaS Platforms in the DMS World for Heavy Equipment Dealers

This week, we are introducing you to a new guest writer, Greg Grady, with his inaugural blog post “The Role of SaaS Platforms in the DMS World for Heavy Equipment Dealers.” Greg Grady has served as the Chief Revenue Officer at Texada Software since January of 2023. Greg has led commercial teams in the heavy equipment, construction and building materials software industries for nearly 20 years. His experience includes working with leading industry-specific SaaS and ERP/DMS software providers worldwide. Greg is an avid NC State fan and lives in Raleigh, NC with his wife Jennifer and twins, Graham & Parker…and Mavis the dog.

Introduction:

In the modern digital era, the utilization of Software-as-a-Service (SaaS) platforms has advanced various industries, including the management of heavy equipment dealerships and rental companies. Dealer Management Systems (DMS) have played a pivotal role in efficiently managing the operations of heavy equipment dealerships for decades. What we are seeing from the leading companies in the space now is the marriage of SaaS platforms with DMS to enhance the overall functionality and productivity of dealers, ultimately increasing dealership profits.

I. Understanding SaaS Platforms:

SaaS platforms refer to cloud-based software solutions accessible over the internet, eliminating the need for costly infrastructure, which requires heavy lifting from the dealer’s IT department. These platforms provide businesses with the flexibility to access applications and services from any device with an internet connection. SaaS platforms typically incorporate mission-critical features such as data storage, advanced analytics, collaboration tools, and automated processes. SaaS solutions in the space are generally specialized, industry-specific solutions like CRM & Quoting, Field Service, Business Intelligence (BI), rental, and e-Commerce systems delivered on modern architected platforms and leverage data from the core DMS. These systems are acutely focused on the high margin departments of a dealership and provide functionality which typically surpasses that of the traditional DMS applications offering similar modules.

II. Dealer Management Systems (DMS):

Dealer Management Systems are comprehensive software solutions designed to manage the various aspects of heavy equipment dealers and rental companies, including inventory management, sales, service, and parts management. DMS platforms work well at streamlining core operations, increasing efficiency, and improving customer satisfaction by integrating multiple functions into one centralized system and dataset.

III. Integration of SaaS Platforms with DMS:

Enhanced Data Management: SaaS platforms allow heavy equipment dealers to manage large volumes of data generated by DMS effectively. The cloud-based approach of SaaS platforms ensures data accessibility, enhanced security, and fluid scalability. Through seamless integration, SaaS platforms can handle “anywhere you need it” data analytics, reporting, and accurate forecasting, enabling dealerships to make informed decisions based on real-time insights.

Mobility and Accessibility: SaaS platforms enable dealers and rental companies to access critical system functionalities from anywhere, using various devices. This ensures sales representatives, service technicians, and other personnel can retrieve essential information on the go, improving response times and customer service. Additionally, remote access to DMS data via SaaS platforms facilitates collaboration and communication among different departments within the dealership, creating a transparent operation.

IV. Benefits of SaaS-DMS Integration for Heavy Equipment Companies:

Cost-effectiveness: SaaS platforms eliminate the need for heavy upfront investments in hardware and software installations, reducing overall IT costs. Additionally, the pay-as-you-go model allows dealerships to only pay for the services they require, enhancing the ROI.

Improved Efficiency: Integrating SaaS platforms with DMS streamlines processes, reduces manual work, data synching issues and enhances overall operational efficiency. Automated workflows, real-time data updates, and centralized information enable faster decision-making and smoother operations.

Enhanced Customer Service: SaaS-DMS integration enables heavy equipment dealers to provide superior customer service through improved response times, accurate data, and personalized interactions. Dealerships can track customer interactions and preferences, allowing them to offer tailored services and build long-term customer relationships. This modern paradigm allows forward-thinking dealers and rental companies to become incredibly “sticky” for their customers.

Conclusion:

SaaS platforms have become integral to the functioning of DMS in the heavy equipment industry. The seamless integration of these platforms allows the DMS to do what it does best, act as the system of record, and the SaaS applications to exploit every business opportunity via optimized workflows in the key departments that drive every dealership and rental business. As heavy equipment dealerships continue to embrace digital transformation, the integration of SaaS platforms with DMS will play a crucial role in their success in the ever-evolving business landscape.

Did you enjoy this blog? Read more great blog posts here.

For our course lists, please click here.

Open Eyes on the Road

Open Eyes on the Road

Guest writer Andy Fanter takes us through the drive he made today in his blog post, “Open Eyes on the Road.” There are hopeful signs everywhere.

I want to tell you about the 100-mile drive on US HWY 56 I made today, Marion to Great Bend, went through McPherson population 14 000, and ending in Great Bend population 14.500. You may have heard of McPherson, home of McPherson College with largest endowment for a college at $1.5 billion. It is known for old car restoration. Great Bend, if you are a duck hunter or bird watcher, is famous for Cheyenne Bottoms and thirty miles south Quivira National Wildlife Refuge.

Here is the summary of construction that I saw today: new building McPherson College, new RV park, new pipeline at natural gas facility, finishing of a 30 acre pond, two major concrete parking lot projects, new Starbucks, new Wendy’s, miles of pavement work on 56, a new hospital, two building demolition jobs, a 5000 square foot slab waiting for a building. This is what I saw today in nowhere—not Wichita or KC or the Topeka-Lawrence-KC corridor.

I saw several trucks with a variety of machines in both directions. I saw more windmill parts heading to sites. I saw everything from a CAT scraper to a wheeled skid steer. I also saw six reasonably new RVs for sale in people’s yards—it looks like the toys from 2020 got expensive to keep, and people got too busy to use them. The weather up until now has been great for the outdoors in Kansas.

What does this mean to the dealer, the personnel, and the manufacturer—-everywhere is busy, nowhere included. You cannot forget your smaller, more rural accounts. I am seeing billions of dollars per week on the construction sites about big jobs in big places. My drive today confirmed the construction industry is busy, record high busy. It should continue with infrastructure dollars, CHIP plants, and EV plants. I saw smaller plants announced near the Ford Blue Facility near Memphis. Buying a home to be built or under construction is now easier than buying a house in the US. The builders are doing well, buying more land, land that will need machines now and through 2024 and beyond—only 2 to 4 million houses short in the US.

I doubt the major manufacturers can catch up during this cycle, but that is not an excuse to quit trying.

Did you enjoy this blog? Read more great blog posts here.

For our course lists, please click here.

1% Increase in Income Equals 2.6% Reduction in Expenses

1% Increase in Income Equals 2.6% Reduction in Expenses

Guest writer Ron Wilson dives into the financial management scene with this week’s blog: 1% Increase in Income Equals 2.6% Reduction in Expenses. He even touches upon something Ron Slee mentions frequently: the downside of discounts.

During complicated economic times businesses tighten up on expenses, spending, and accounts receivable.

Rafi Mohammed, in his book “The 1% Windfall” provides an additional effort that can assist in meeting the needed changes to the bottom line.

Basically, the concept revolves around increasing income by 1%, without increasing the cost of sales, or reducing direct expenses.

The example below shows that a 1% increase in sales (without impacting cost of sales or direct expense) equals a 2.6% reduction of direct expenses. Apply your organization/department gross profit and pretax percentage to see the impact it has on your own organization.

We have all been through the difficult experience of reducing direct expenses, and it can be very painful.

Here are a few examples that can help to make a positive impact on sales without adjusting the direct expenses areas.

Current Status of Discount Programs– often discount programs are provided to customers based on a request from a salesperson. No doubt the programs may have been needed at a specific point in time, but a review of discount programs may show discounts being given that are not providing the expected increase in sales. Often the OEM provides some type of shared discount program over a specific timeframe. It is important to verify customers’ discounts reflect the OEM’s current program. An OEM may discontinue a rebate program and the dealer may not have applied the same changes and unintentionally may be caring the full burden of the discount being provided to the customer.

Effectiveness of Discount Programs-Verify the discounts are providing the expected results, which is usually increased volume, or expanded use of other products and services within the dealership. If the discount program was not effective, a different approach may need to be reviewed with the sales representative.

Below is a handy website that shows the impact discounting has on gross profits.

The example below applies to a 10% discount on $1 million in sales. Sales need to increase 20% to make up the same dollars.

https://www.growthforce.com/blog/how-giving-discounts-can-destroy-your-business-profits

This can be a great tool to share with the sales representatives when discussing providing a customer with a discount. What can be expected in increase volume over time?

Providing Repair Options can offset the discount a customer is wanting on a component rebuild, for example. Rebuild options providing a “good-better-best” offering can accomplishing the customers rebuild needs within a specific price range. The variable rebuild options allows the dealer to rebuild a component that meets the level of rebuild needed by the customer within a selected price range. The repair options eliminate the “discount” of a full rebuild while providing a price based on the level of rebuild needed by the customer.

Value Based Pricing requires understanding the customers’ needs and priorities. For example, a customer is focused on reducing the hazards/injuries related to changing ground engaging tools (GET) on a piece of mining equipment. Promoting reduction of the number of GET changes will contribute to reducing the hazards as well as downtime to complete the GET change out. It may not always be about the dollars and cents.

When developing value statements your existing customers can be a great resource to find out what value you bring. Ask your customer to explain the real value of your offer. This will provide a view of their perspective, while building relationships with customers and at the same time it gives you a chance to learn an incredible amount of invaluable information.

Below is an example of a value statement that has identified four areas of importance to the customer. This information was taken from an ESCO GET (Ground Engaging Tool) promotional piece. As can be seen there is no discussion about “discounts,” the discussion is related to “value add” offerings:

Increased Machine Availability

Lower Maintenance Costs

Lower Total Parts Expense

Improved Safety

Best of Both Worlds

1% increase in Sales Without increasing Cost of Sales to Improve the Bottomline: It would be unrealist to think the 1% increase model is the only option. No doubt there needs to be a combination of both direct expense management and reviewing the pricing models and programs currently in place. Below are some pros and cons that will show the importance of combining the two:

Advantages of the 1% Increase in Sales to Improve the Bottom Line:

Disadvantages of the 1% increase in Sales to improve the Bottom Line:

Reducing Direct Expenses to Improve the Bottomline:

The best Solution is a Blending of the Two:

Take some time to review the various recommendations provided in “The1% Windfall”, while reviewing the rest of your key performance indicators, to provide a balanced improvement to the overall financial results.

Did you enjoy this blog? Read more great blog posts here.

For our course lists, please click here.

Friday Filosophy v.07.21.2023

Friday Filosophy v.07.21.2023

We are back with a Friday blog post today! Please read some quotable quotes from various authors (our founder Ron Slee included!) in Friday Filosophy v.07.21.2023

Let’s focus on a different direction. We will start this off with what people call “Sleeisms.”

We will continue with quotes from others, just to be well-rounded today:

The Time is Now.

Did you enjoy this blog? Read more great blog posts here.

For our course lists, please click here.